3D Printing

A high-level overview of the field of 3D printing and the solutions we provide.

What is 3D printing?

3D printing, also known as additive manufacturing, has transformed the way we create and produce objects.

The technology enables the creation of physical objects from digital designs. It works by using a computer-aided design (CAD) software to create a 3D model, which is then sliced into thin layers. These layers are sent to a 3D printer, which builds the object layer by layer using a variety of materials, such as plastics, metals, and ceramics.

3D printing has revolutionized manufacturing by allowing for the rapid prototyping and customization of products, reducing costs, and lead times. It is used across industries, including aerospace, healthcare, automotive, and education, among others, and continues to push the boundaries of what's possible in manufacturing.

As 3D printing technology continues to evolve, its applications are expanding. Researchers are exploring the use of 3D printing to create human organs, food, and even buildings. With its potential to disrupt traditional manufacturing processes and enable new possibilities, 3D printing is a technology to watch in the years ahead.

The Subfields of 3D Printing:

Fused Deposition Modeling (FDM)

FDM is a 3D printing technology that builds objects layer by layer using a melted thermoplastic material. It is a low-cost option and ideal for large-scale objects. FDM printers are relatively simple to operate, making them a popular choice for home users and hobbyists. However, they may not be suitable for producing high-resolution prints.

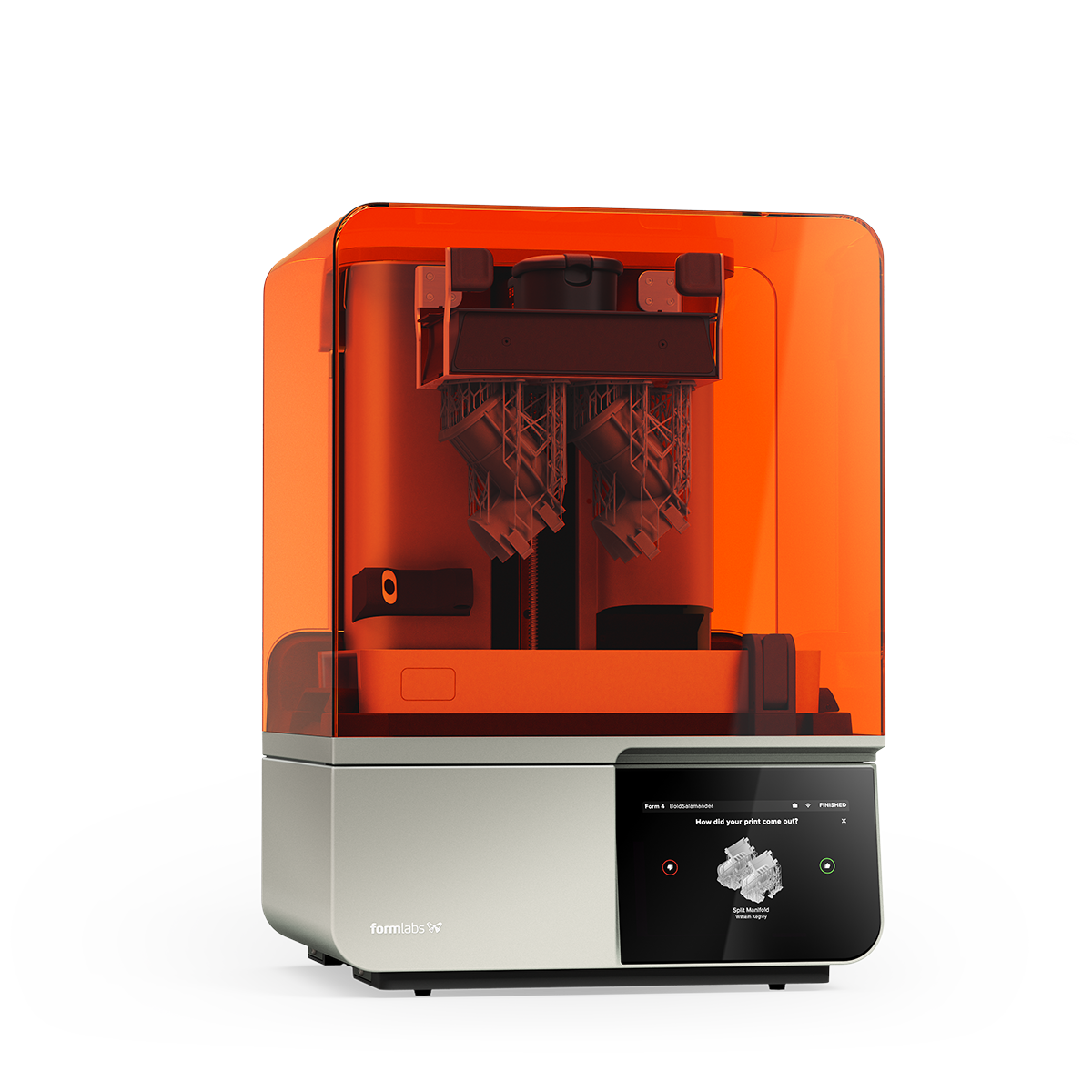

Stereolithography (SLA)

SLA uses a UV laser to solidify a liquid resin into a solid object. It is a high-precision 3D printing technology that can produce extremely detailed models with intricate features. SLA is often used in industries such as dentistry and jewelry-making, where accuracy is crucial.

Selective Laser Sintering (SLS)

SLS is a 3D printing technology that uses a laser to fuse powdered material, such as nylon or metal, into a solid object. SLS is particularly useful for producing complex geometries, such as parts with internal cavities or intricate shapes. It can also produce strong and durable prints, making it a popular choice for industrial applications.

Digital Light Processing (DLP)

DLP uses a projector to cure a liquid resin into a solid object. It is similar to SLA but faster and lower cost. DLP printers can produce high-resolution prints with smooth surfaces and fine details, making them a popular choice for applications such as jewelry-making and model-making.

Binder Jetting

Binder Jetting is a 3D printing technology that uses a liquid binder to bond together layers of powder material, such as sand or metal. It is particularly useful for producing metal parts and sandcasting molds. Binder Jetting is a fast and cost-effective way to produce high-quality prints in a variety of materials.

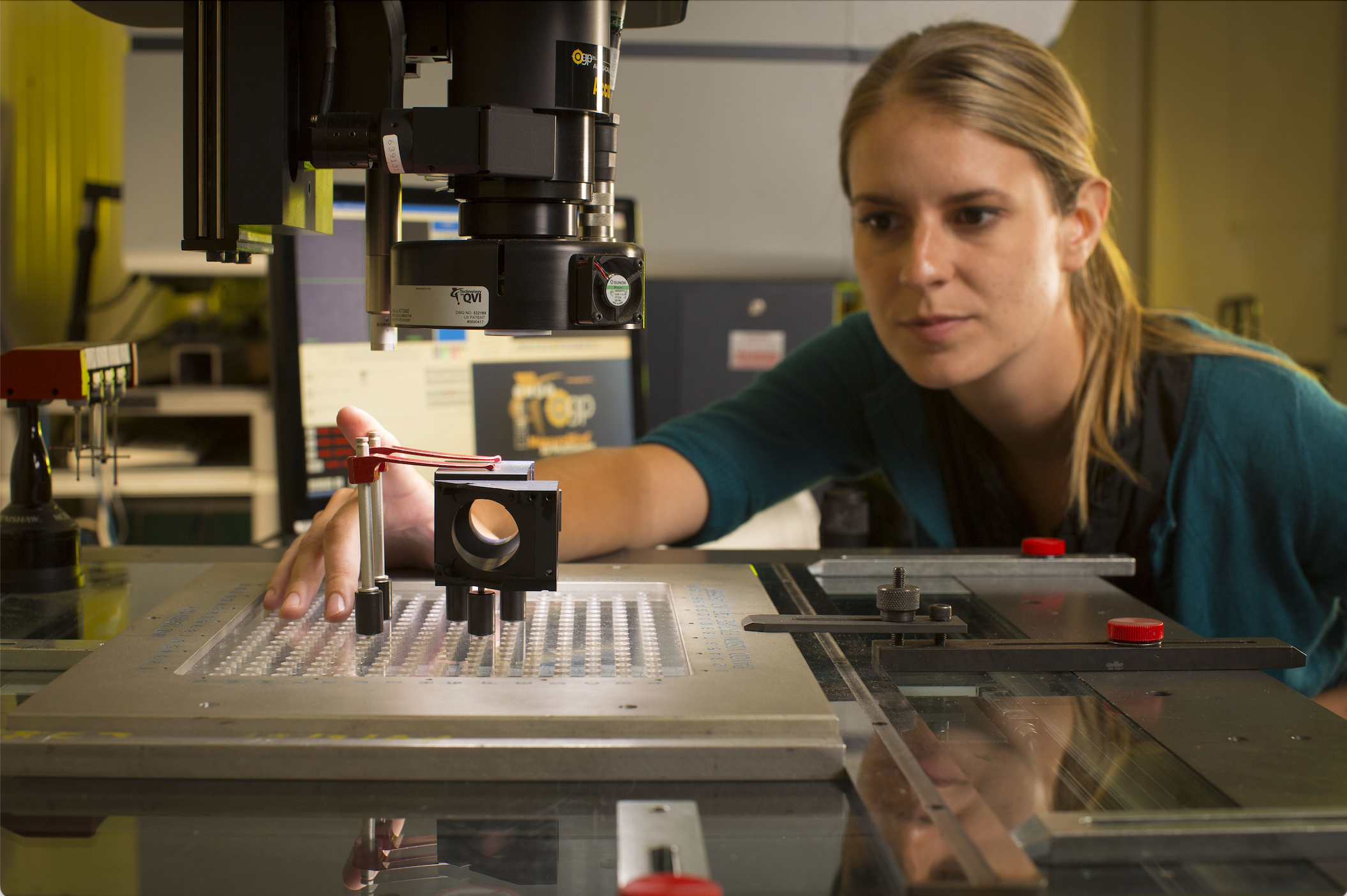

Our Core Competencies in 3D Printing

Our expertise in design and engineering allows us to create custom designs that are optimized for 3D printing, taking into account material properties and the limitations of different 3D printing technologies.

We also have extensive experience with a wide range of materials, including metals, plastics, and composites, and can help clients choose the best material for their specific application. Our deep understanding of 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP) enables us to advise clients on the best technology for their project.

At Indicate Technologies, we are committed to using the latest 3D printing software and tools to ensure the highest quality prints possible. Our investment in advanced software for design and simulation, as well as state-of-the-art 3D printers, means that we can produce parts with exceptional accuracy and resolution.

We can help bring your ideas to life with precision, speed, and quality.