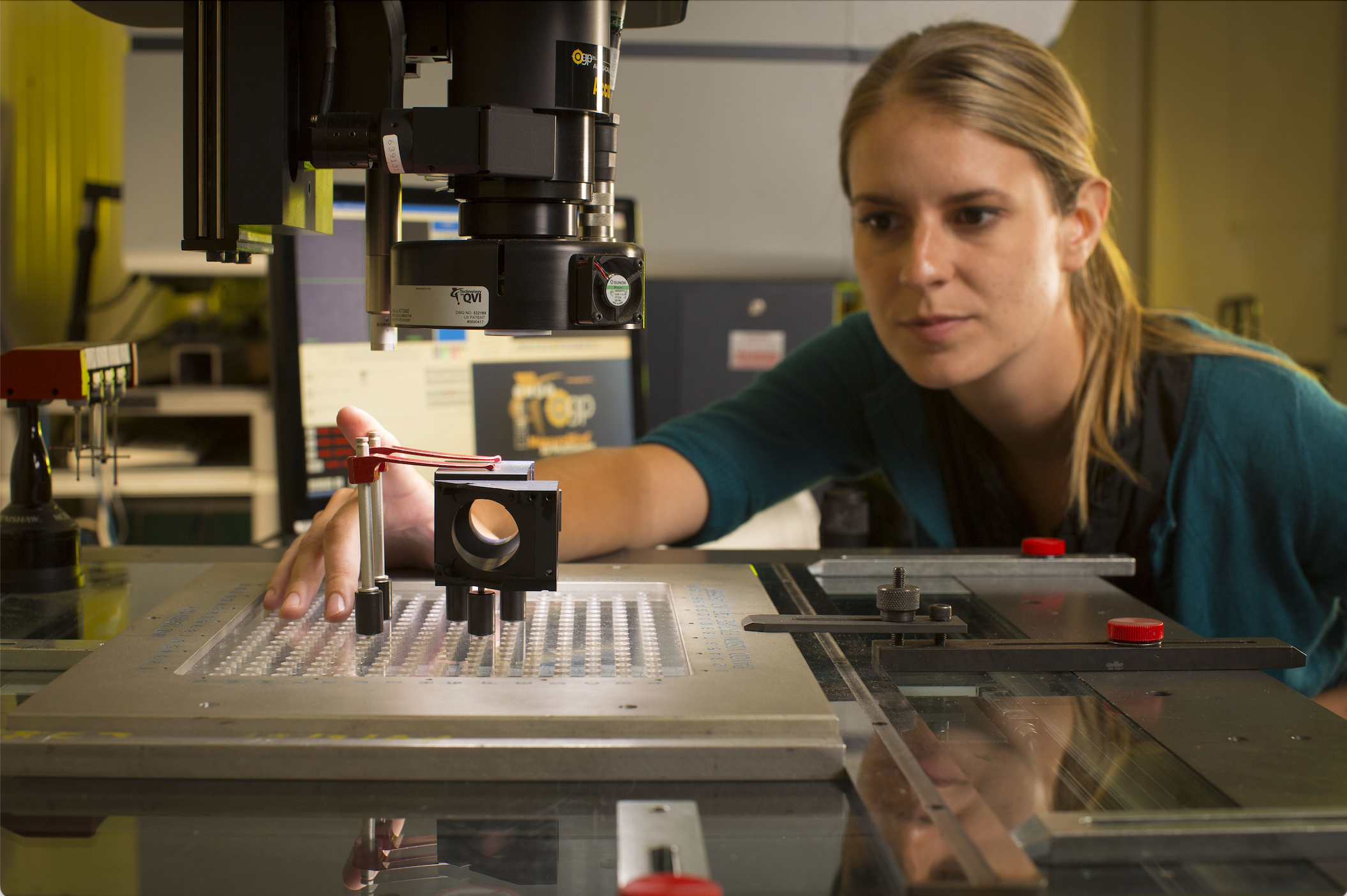

Metrology is defined as the science of measurements.

Why is metrology important?

Metrology plays a crucial role in manufacturing by ensuring equipment calibration for precise production and verifying compliance with regulations, design specifications, and customer expectations.

What is calibration?

Calibration involves comparing a measuring instrument with: (a) a primary standard, (b) a known input source, (c) a secondary standard with higher accuracy than the instrument being calibrated.

Metrology plays a crucial role in manufacturing by ensuring equipment calibration for precise production and verifying compliance with regulations, design specifications, and customer expectations.

What is calibration?

Calibration involves comparing a measuring instrument with: (a) a primary standard, (b) a known input source, (c) a secondary standard with higher accuracy than the instrument being calibrated.

Why is calibration important?

Calibration of measuring equipment is important to find and correct any deviations or errors and to ensure traceability.